Eddy

currents are currents which circulate in conductors like swirling eddies in a

stream. They are induced by changing magnetic fields and flow in closed loops,

perpendicular to the plane of the magnetic field. They can be created when a

conductor is moving through a magnetic field, or when the magnetic field

surrounding a stationary conductor is varying i.e. anything which results in

the conductor experiencing a change in the intensity or direction of a magnetic

field can produce eddy currents. The size of the eddy current is proportional

to the size of the magnetic field, the area of the loop and the rate of change

of magnetic flux, and inversely proportional to the resistivity of the

conductor.

Like any

current flowing through a conductor, an eddy current will produce its own

magnetic field. Lenz’s Law states that the direction of magnetically induced

current, like an eddy current, will be such that the magnetic field produced will

oppose the change of magnetic field which created it. This resistance created

by the opposing magnetic fields is exploited in eddy current braking, which is

commonly used as a method of stopping rotating power tools and rollercoasters.

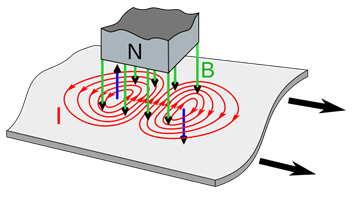

In the

diagram below, the conductive metal sheet (representing the moving

rollercoaster car or power tool for instance), moves past a stationary magnet. As

the sheet moves past the left edge of the magnet, it will feel an increase in

magnetic field strength, inducing counter-clockwise eddy currents. These

currents produce their own magnetic fields and according to Lenz’s Law, the

direction will be upwards i.e. opposing the external magnetic field, creating

magnetic drag. At the other edge of the magnet, the sheet will be leaving the

magnetic field and the change of field will be in the opposite direction, thus

inducing clockwise eddy currents which then produce a magnetic field acting

downwards. This will attract the external magnet, also producing drag. These

drag forces slow the moving sheet, providing the braking. An electromagnet can

be used for the external magnet, meaning it is possible to vary the strength of

the braking applied by adjusting the current through the electromagnet’s coils.

An advantage of eddy braking is that it is contactless, so results in no

mechanical wear. However, eddy braking is not suitable for low speed braking and

because the conductor has to be moving, eddy brakes cannot hold objects in

stationary positions. Thus, it is often necessary to also use a traditional

friction brake.

Eddy

currents were first observed in 1824 by scientist and then Prime Minister of

France, François Arago. He realized that it was possible to magnetize most

conductive objects and was the first to witness rotary magnetism. Ten years

later, Lenz’s Law was postulated by Heinrich Lenz, but it wasn’t until 1855

that the French physicist Léon Foucault officially discovered eddy currents. He

found that the force needed to rotate a copper disk when its rim is placed

between the poles of a magnet, such as a horseshoe magnet, increases and the

disk is heated by the induced eddy currents.

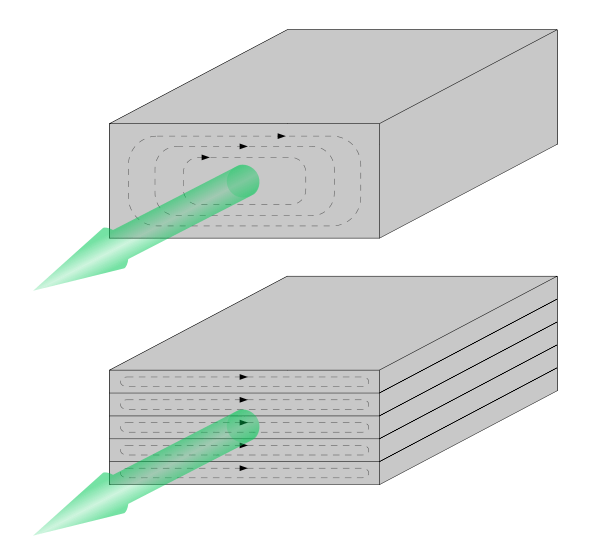

The heating

effect originates from the transformation of electric energy into heat energy

and is used in induction heating devices, like some cookers and welders. The

resistance felt by the eddy currents in a conductor causes Joule heating and the

amount of heat generated is proportional to the current squared. However, for

applications like motors, generators and transformers, this heat is considered

wasted energy and as such, eddy currents need to be minimized. This can be

achieved by laminating the metal cores of these devices, where each core is

made up of multiple insulated sheets of metal. This splits the core in many

individual magnetic circuits and restricts the flow of the eddy currents

through it, reducing the amount of heat generated through Joule heating.

Eddy

currents can also be removed by cracks or slits in the conductor, which break

the circuit and prevent the current loops from circulating. This means that

eddy currents can be used to detect defects in materials. This is called

nondestructive testing and is often used in airplanes. The magnetic field

produced by the eddy currents is measured, where a change in the field reveals

the presence of an irregularity; a defect will reduce the size of the eddy

current, which in turn reduces the magnetic field strength.

Another

application of eddy currents is magnetic levitation. Conductors are exposed to

varying magnetic fields which induce eddy currents within the conductor and

produce a repulsive magnetic field, pushing the magnet and conductor apart.

This alternating magnetic field can be caused by relative motion between the

magnet and conductor (generally the magnet is stationary and the conductor

moves) or with an electromagnet applied with a varying current to vary the

magnetic field strength.